Automated Produce Equipment

www.automatedproduceequip.com

Upmatic Master Bagger/Baler, Columbia Okura Robotic Palletizer

Automated Produce Equipment’s Upmatic Master Bagger/Baler, which is in use in potato and onion sheds, allows for the re-allocation or reduction of labor on the end of the line.

The addition of a Columbia Okura robotic palletizer is also value added as a labor-saving installation. Robotic palletizers typically have a lower acquisition cost and have fewer moving parts than traditional machines. Other benefits include the elimination of injuries and workers’ compensation claims associated with pallet stacking.

Chinook Equipment, Inc.

www.chinookequipment.com

edp Electro-bagger

The new edp Electro-bagger model AB-2218-DF has the ability to handle bags as well as cartons and reusable plastic containers (RPC). All that is needed is an optional set of carton holders, and operators can use the touchscreen to select bags, cartons or RPCs. There is no need to move machinery to make the changeover. Users can also control the belt speeds with the touchscreen, as well as the speed of the entire machine and the “no bag photo eye.” These adjustments can be made at any time, even if the machine is in operation.

Push-button control of the bag clamps is now included as standard equipment for this model, providing ease of use. The latest design also features a larger in-feed area from the belts to the bag holder to allow for larger produce.

EZ-Tarp

www.ez-tarp.com

Automatic Truck Tarper

The EZ-Tarp is a fully automated tarp that is easy to install and is completely operational from the truck cab. Workers won’t be walking on the crop with the EZ-Tarp deployed. It is designed to make covering and uncovering truckloads safer, faster and easier.

Kerian Machines

www.kerian.com

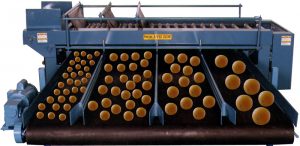

Speed Sizer

The Kerian Speed Sizer will gently and accurately sort potatoes by size. It is affordable and proven in use for both long (russet) potatoes and round potatoes including reds and whites. With 13 standard models, the Kerian Speed Sizer can fit applications from small packing lines to large processing plants.

The constantly rotating rollers provide consistent and precise sizing that is fast, gentle, accurate and easily adjustable. Stainless steel models and stainless steel contact points are also available. The sizer offers each grower a maximum value and a machine perfectly suited to their capacity and number of sizes.

Milestone

www.milestone-equipment.com

Inline Sizer, AccuSizer

Milestone’s inline sizers and AccuSizers offer gentle and accurate sizing in a compact package. Standard inline sizers are available in numerous configurations and can incorporate the company’s proprietary quick adjust and sizing star for increased sizing accuracy. The AccuSizer has been many growers’ go-to for washed or peeled potatoes for over 30 years. The tried-and-true design, along with robust construction, has earned the AccuSizer a reputation of precise and low-maintenance operation.

Trinity Trailer Mfg., Inc.

www.trinitytrailer.com/spuds

Ultra Spud Tail Fin

Unloading spuds can be an ordeal – both for the potatoes and the drivers hauling them. During unloading, potatoes can take a hard fall to the piler or conveyer belt, bruising the product. Or potatoes can bounce off the conveyor belt, smashing onto the ground and spoiling the spud.

Trinity Trailer Mfg, Inc., an Idaho-based belt trailer manufacturing company, engineered a simple solution for its trailers: the Ultra Spud Tail Fin. This unique feature is simplifying life for haulers of potatoes and other agricultural commodities.

The 24-inch shaft mount tail fin extension and its tapered edges gently funnel the cascading potatoes – or beets, onions and other commodities – onto the piler or conveyer belt. The cleaner unload produces less waste, meaning less time clearing spoiled spuds from the receiving area and more time back on the road.

Western Trailers

www.westerntrailer.com

Western Spud Express Trailers

Lightweight innovation is in Western Trailers’ DNA. In 1972, when customers needed to move more spuds per load, Western Trailers designed the first Spud Express. It was and still is among the lightest weight high quality trailers on the market. Western’s use of high tensile steel in the chassis, state-of-the-art paint process and aircraft aluminum body provide a trailer that will survive the toughest conditions that the potato industry can throw at it, along with maintaining its good looks for years to come.

Western Spud Express trailers deliver more to growers’ bottom line with more spuds per load along with high resale values.