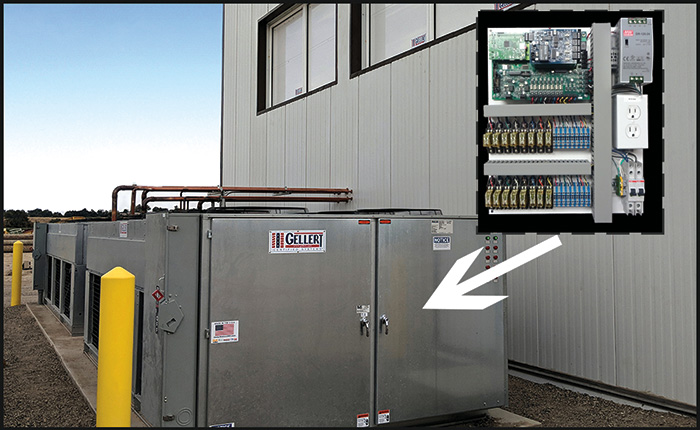

Gellert

Refrigeration Controller

Gellert’s new Refrigeration Controller, which can be installed directly into new or existing refrigeration units, is designed to maximize energy efficiencies. This technology has the ability to monitor refrigeration equipment, providing advanced warnings of potential failures.

Among many other features, it provides the ability to rotate between multiple compressors, sidestepping the risk of any one compressor getting overworked. And while the Gellert Refrigeration Controller is running multiple compressors, if a single compressor fails, the others will continue working so users don’t experience a complete shutdown.

Condenser fans can be rotated, increasing the lifespan of all motors. They can also be controlled from a fixed discharge setting or a floating pressure based on outside temperature, maximizing energy efficiency.

Greentronics

Yield Monitor

Integration with John Deere GS3 2630 displays is now available. Greentronics’ yield monitor transmits yield data to the 2630. The 2630 displays and stores yield data in real time. Integration to Trimble FMX and TMX displays continues to be available, as well.

Greentronics yield monitors are designed for root crop and vegetable harvesters. The system is built around one or more load cells, which are installed in a conveyor to measure the weight of the crop as it passes on the belt.

Once installed and calibrated, the harvester operator chooses the field name and sets the swath width. The operator does not need to interact with the yield monitor while harvesting.

Growers use yield maps to study and manage variability in their fields and generate report cards on their progress. By applying breakeven points, yield maps can indicate areas with profit and loss and help make decisions about inputs, population density, crop rotation, cover crops, drainage, leveling and so on.

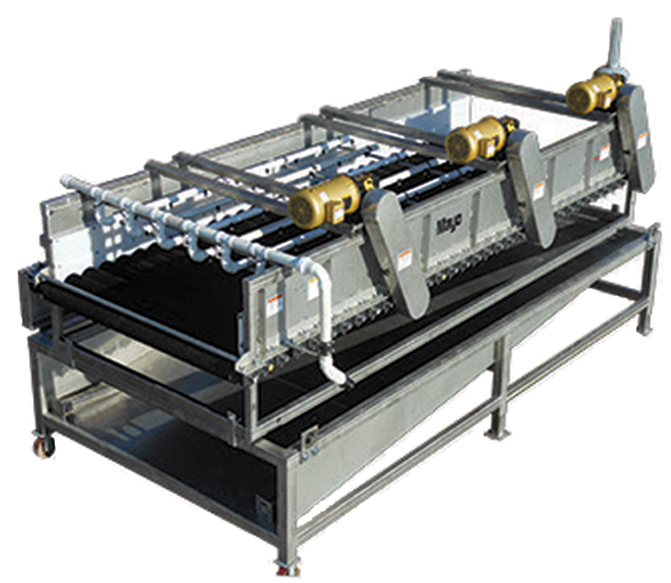

Mayo Manufacturing

Washers

Mayo Manufacturing Co. provides washers for various areas of potato production. Different styles are available depending on the category needed. The most common are the brush washers (as pictured), which are used for table, chip and process potatoes. The washers come in many sizes and are available in standard or stainless steel.

The barrel washer is used primarily for chip and process potatoes. It is often portable and can be used when shipping potatoes.

The washer-polisher uses a combination of rotating brushes within a rotating drum to prepare table potatoes for market.

Rietveld Equipment

Polisher

The Allround Polisher TD 350-18 has 18 rolls of brushes with an estimated capacity of 25 tons per hour. Three smaller models are also available. The polishers are available in stainless steel and feature a hydraulic lift for easy cleanout, variable speed control, a water recirculation system and water cleaning system. The machine also offers easy brush removal for changing the brushes, as well as several different types of brushes for each application.

Allround builds all of the machines required in a washing/grading line, and the machines are running in over 80 countries worldwide.

Rietveld Equipment offers free 2D and 3D drawings of full lines, or drawings of the available machines in users’ existing lines.

Parts and machines are in stock at the company’s Midwest facility, and service and support from certified technicians is available 24 hours a day, seven days a week.

Spudnik

High-Capacity Storage System

The Spudnik High-Capacity Storage System will increase the efficiency of the harvest season. The system includes the new model 1872 Even Flow Bin, a 990 or 994 Eliminator, 1205 and 1255 Conveyors, and an 880 Piler. This high-capacity system will increase the storage rate up to 6,000 sacks an hour, allowing growers to get more done in the critically short timeframe of harvest.

The Spudnik 1872 Even Flow Bin has a capacity of 600 sacks and a 72-inch elevator and bottom belt. A consistent, even flow of product is the key to the success of the high-capacity system. The hydraulically controlled back door sets the flow into the eliminator and can be raised completely out of the way of the product for increased flow or to accommodate varieties with sensitive skin. The 42-inch conveyor line moves the large volume of potatoes gently and smoothly through the storage to the 48-inch piler.

Lockwood Manufacturing

Windrower

Lockwood’s lineup of windrowers adds efficiency and value to potato operations. Managing time and product flow during harvest is critical to earning the highest profits.

The Lockwood 656DD Windrower, a six-row machine, includes a double discharge, allowing growers to dump potatoes in two different rows to improve harvester efficiency. Also available is the patented telescoping rear cross, allowing for either a left- or right-hand discharge. For better depth control, Lockwood has added pressure-sensing support wheels, as well. Last but not least, the 656 Windrower offers excellent visibility.

Logan Farm Equipment

Stac Pro Bin Piler

The Logan family of potato field handling equipment has a newly designed bin piler with three sizes available and individual boom belts with flexibility for trans-loading and storage loading.

The new Stac Pro piler features hydraulic sliding ballasts for optimal weight distribution during towing and piling, as well as a hydraulic telescoping hitch to ease towing hookup. To further aid transport, the wheels fully disengage for towing at highway speeds.

A high/low gear is used on the wheel drive, ensuring flexibility, and the Stac Pro employs exaggerated 15-degree troughing of booms for high capacity without friction against the conveyor sidewalls.

The Stac Pro comes with a high-tech Eaton two-way remote control with simple three-function joystick for precise boom control. The remote offers troubleshooting codes, oil temperature monitoring, machine run hours, full machine control and emergency stop.