By Bob Hesse, Director of Suberizer Research and Development

Since the mid-1960s when J. R. Simplot shook hands with Ray Kroc to supply frozen French fries to McDonald’s, potato storage has come a long way. During the roughly 50 years since those first potato storages were conceived, ag schools, processors and the raw product storage industry have been on a constant quest to minimize potato losses and maintain product quality during storage.

Today, the notion that fanhouse arrangement, system details, storage structure and engineering must all be integrated to produce the most cost-effective storage is evident. The details necessary to get tightly-controlled air temperature and humidity generated by the system in the fanhouse uniformly distributed to the product in storage are known and understood.

The blow-through humidification cell provides maximum adiabatic cooling, assures minimum weight loss and maximizes product quality during storage.

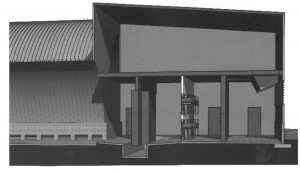

A well-designed Suberizer Curve storage structure, for example, coupled with current technology in a properly engineered external fanhouse, has proven to provide storage managers an important tool to minimize losses and maintain quality during storage. This storage incorporates details developed in that 50-year history of the raw product storage industry.

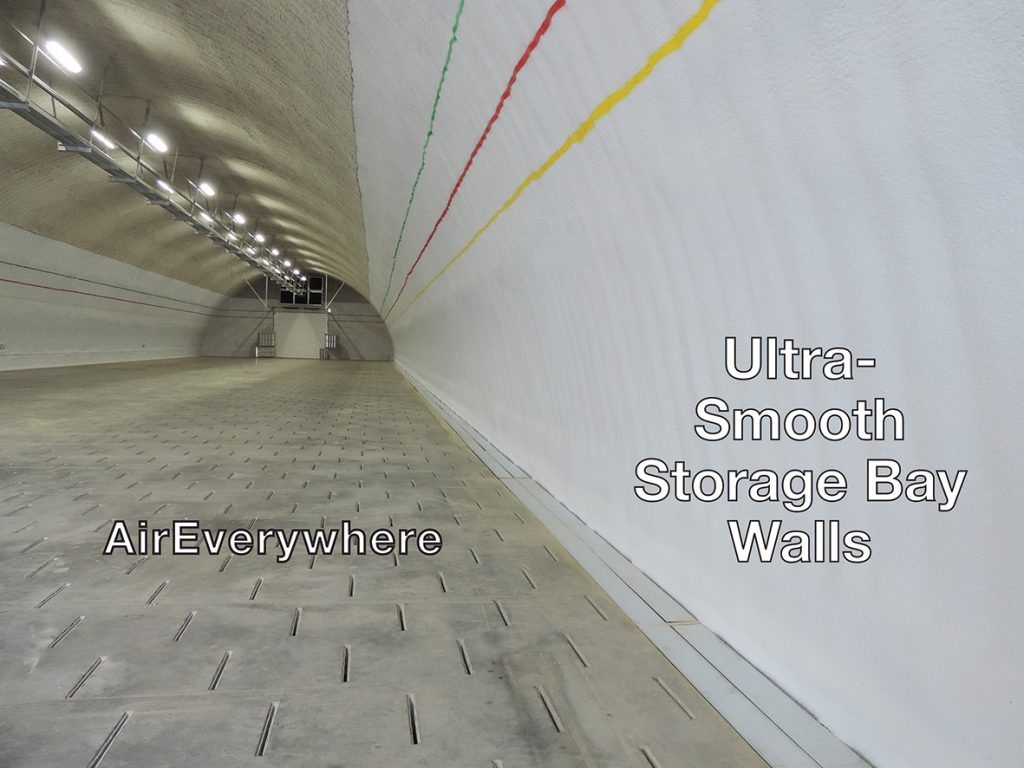

It’s all about assembling engineering details. An ultra-smooth storage bay interior wall significantly enhances insulation performance, minimizes product damage and contributes to good air distribution. A properly designed plenum and storage bay with AirEverywhere under-floor concrete air distribution and uniformly spaced vent holes also plays an important role.

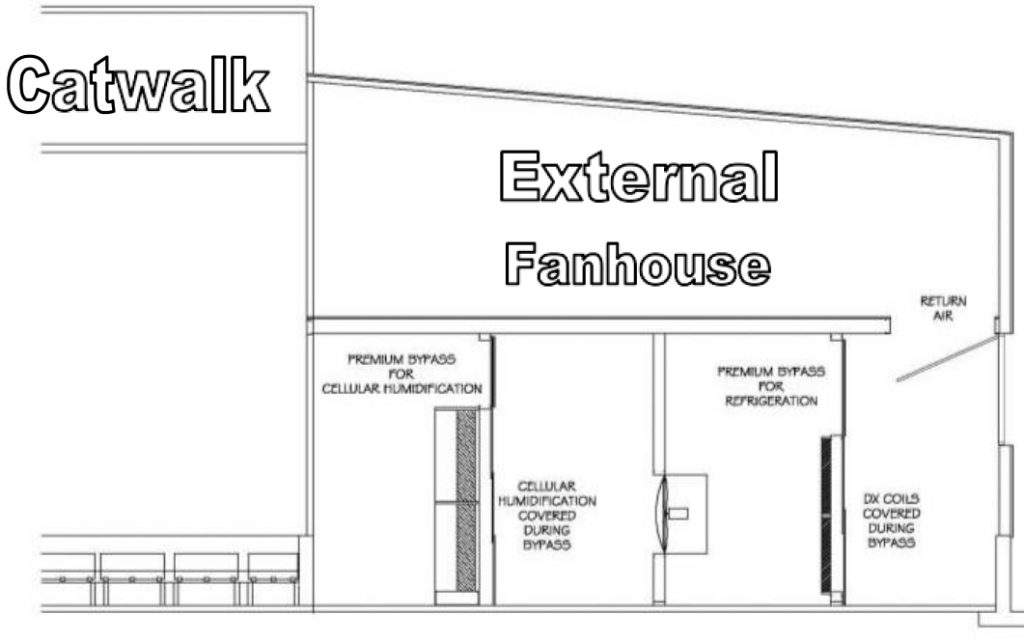

Similarly, a well-engineered external fanhouse, properly paired with storage and air flow distribution details, provides essential performance benefits including:

• Effective correlation of system performance and system operation

• Significant enhancement of uniform air distribution to the pile

• Enhanced uniform sprout-inhibitor distribution to the pile

• Efficient blow-through humidification cell for maximum adiabatic cooling

• Premium humidification cell automatic

bypass from control panel, remote PC or cell phone, with the humidification cell completely covered during bypass• Premium automatic DX bypass from control panel, remote PC or cell phone, with the refrigeration DX panels completely covered during bypass

• Both return and fresh air can be automatically or manually selected for refrigeration

• Cost-effective system maintenance arrangement

• Effective and complete under-floor duct cleaning design

• Direct access to top of pile from fanhouse for premium

storage management• Direct access to top of pile from fanhouse for sample collection.